Sauer Compressors‘ 3-stage air cooled starting-air compressors

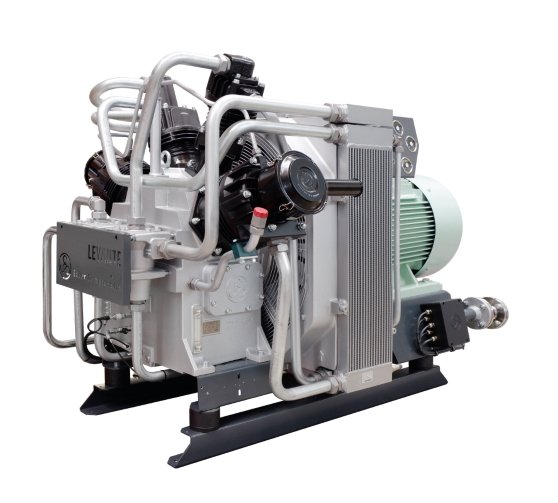

With the new 3-stage air cooled compressors of the Levante series, Sauer Compressors offers highly reliable and low-maintenance starting-air compressors, thus setting the worldwide standard.

Compressors for starting air are indispensable for the shipping industry. If the compressors on board do not work, the engines cannot be started and entering a port is not permitted. This will remain the case in the future, since starting air is always required, regardless of whether a ship is fueled with heavy fuel oi, marine diesel or liquefied natural gas (LNG). The demands on marine compressors are therefore high. Besides being absolutely reliable, they should have to be maintained easily and as little as possible, they have to fit into tight spaces and have a long service life.

Air cooled compressors on the advance

With the development of the Levante series, Sauer presents a new range of 3-stage air cooled compressors which are tailored to the high requirements of international shipping. In comparison with conventional two-stage water-cooled starting-air compressors, they provide a number of advantages. As they do not require cooling water, it is unnecessary to install and maintain cooling water systems. In addition, temperatures remain moderate during compression, unlike in the case of their water-cooled counterparts. The lower thermal load during operation is a major advantage, since the service life of wearing parts can be approximately doubled. One reason for this is that no clogging due to coking occurs. While the valves of water-cooled compressors need to be serviced after about 1,000 to 2,000 hours of operation, the valves of air cooled compressors can be used for 4,000 hours in the first and second stage and for 2,000 hours in the third stage.

Innovative design

Sauer is breaking new ground with the design of the Levante series. One unique selling point is the use of block coolers in all three stages. All other compressors in this field use an inefficient tube cooler in the third stage at the latest. The cooling unit is located between the motor and the compressor. This optimizes the air flow and conceals moving components. Because of this, the compressor is significantly safer in operation and maintenance. Moreover, it ensures that the crankshaft exhibits fewer interruptions that need to be sealed. A further novelty is the split cylinder which can be removed more easily than a cylinder in one piece, facilitating maintenance a lot. Assembly is also easy and less prone to errors.

Space is scarce

The smaller, the better: This applies to all ship technology and is particularly true for small and medium-sized ships as wells as cruise-liners. In the cruise sector, no technical equipment can be installed above the waterline, because this is where passengers need space. Below deck, however, there is hardly any space since the ships have little draught in order to call at destinations in shallow waters. The Levante series compressors have therefore been designed particularly space-saving. The compact design is furthered by the low temperatures of the compressors: As all directly accessible surfaces heat up only moderately, no space-consuming railing is required.

Operating costs in view

Compared with the purchase price of a ship, the initial costs for the compressor package are almost negligible. For shipping companies and owners, the expenses for operation and maintenance as well as the service life of the compressors are much more important. Thanks to the high fill-up capacity of up to 460 m³/h in the Levante series, even large ships require only a few compressors. Most of the world’s largest container ships already use Levante compressors. Even with high transport capacities of over 23,000 TEU, only up to four compressors of the largest type Levante WP 460 L Marine are used. Already before the official sales launch, the series proved its suitability. During a field test, about 8,000 operating hours were achieved on six ships of three shipping companies. Subsequently, the compressors showed hardly any wear on pistons and cylinders, and the oil turned out to be cleaner than average thanks to the new oil filter.

User-friendly and safe

During the development of the Levante series, special attention was paid to user-friendliness. The compressors have a modern user interface with integrated pressure gauge panel that bundles all important data at a glance. In the past, operators had to read off values at various spots on the compressor, because the pressure gauges were installed directly at the respective stages.

Maintenance with guarantee

To ensure reliable and long-term operation, Sauer offers its maintenance concept which is customized for shipping, Sauer Easy Care. The concept distinguishes four maintenance kits for four intervals. For each maintenance stage, a kit with all spare parts is available. When the parts are used completely and correctly at the recommended intervals, reliable operation is guaranteed, unlike with grey market parts of unclear origin. Offering complete kits makes it easier for operators to order spare parts, and it also simplifies budget planning and eliminates the need for costly warehousing. On top, there is the certainty of always using fresh parts. This is particularly important for seals that become brittle and thus unusable if they are stored for too long.

At home on the largest ships

Designed for ships with a capacity of over 5,000 TEU, the Levante series is at home on the largest ships of the world. This includes container ships with a length of just under 400 m, a beam of over 61 m and a draught of 16 m. Such ships can carry over 23,000 TEU, and they are usually equipped with three Sauer Levante WP 460 L Marine.

Box:

Sauer Compressors is a medium-sized German group of companies with twelve international subsidiaries. The company was founded more than 130 years ago, and has over 80 years’ experience in compressed air technology. Today, it focusses on the development, production and sale of medium- and high-pressure compressors for applications in navy, commercial shipping, offshore and industries. The modern reciprocating compressors for the compression of air as well as neutral and inert gases reach pressures of 20 to 500 barg. For each area of application, Sauer offers customized solutions for individual customers, OEMs and companies that operate on a global stage. With a worldwide network of agents and representatives, Sauer Compressors maintains close proximity to its customers. By supplementing the compressor range with high-quality accessories, engineering services, assembly and service concepts, Sauer offers system solutions and compressed air modules right up to complete turnkey installations.

Source www.azetpr.com

.jpg)